Your AC is running, the fan’s spinning, but zero cold air is coming out. You check the thermostat—it’s set right. You check the vents—they’re open. Then you hear it: nothing. The outdoor unit isn’t making that familiar humming sound. Your compressor just died, and in the middle of a Texas summer, that’s basically a crisis.

Here’s the deal—your AC compressor is the heart of your cooling system. When it stops working, your AC can’t cool at all. The good news? We can walk you through what went wrong, what it’ll cost to fix, and whether repair or replacement makes more sense for your situation.

Quick Facts: AC Compressor Failures in Texas

- Compressors are expensive to replace: We’re talking 1,200 to 3,500 dollars depending on unit size and brand. Sometimes full system replacement makes more financial sense.

- Texas heat kills compressors faster: Constant summer use and high ambient temperatures stress compressors way more than in milder climates. Lifespan here is often shorter.

- Warning signs show up early: Weird noises, warm air, breaker trips—these signal problems before total failure. Catching them early saves money.

- Running a failed compressor damages other parts: Don’t keep using your AC if the compressor’s struggling. You’ll wreck the capacitor, contactor, and potentially the whole system.

- Regular maintenance extends lifespan: Annual tune-ups catch minor issues before they kill your compressor. It’s way cheaper than emergency replacement.

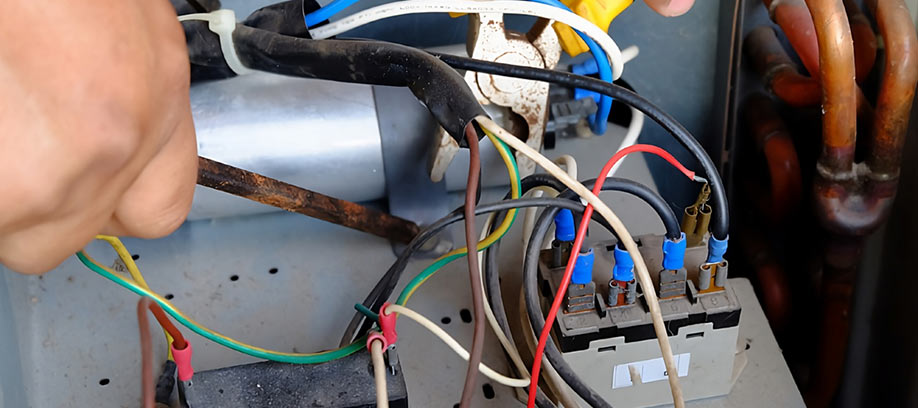

- Electrical issues are common culprits: Power surges, bad capacitors, and faulty wiring can fry compressors. This is why surge protectors matter.

How Your AC Compressor Actually Works

The compressor sits in your outdoor unit and does exactly what its name suggests—it compresses refrigerant gas, cranking up the pressure and temperature. That hot, pressurized gas then flows through your system, releases heat outside, and returns as cool liquid to your indoor coil.

Think of it like your AC’s engine. Without it running smoothly, nothing else works. The fan can blow all day long, but if the compressor isn’t compressing refrigerant, you’re not getting cold air. Period.

This cycle runs constantly when your AC is on, which is why compressors take such a beating in Texas. We run AC from April through October—sometimes longer. That’s six months of nonstop work.

Signs Your AC Compressor Is Failing

Compressors don’t usually die without warning. Here’s what to watch for before total failure hits.

AC Runs But Won’t Cool

System’s on, fan’s blowing, but the air isn’t cold? Your compressor is probably struggling to compress refrigerant properly. This is often the first sign something’s wrong.

Unusual Noises From the Outdoor Unit

Humming, clunking, rattling, grinding—none of these are normal. They usually mean internal mechanical problems like worn bearings, loose components, or electrical issues. The longer you ignore the noise, the worse it gets.

Circuit Breaker Keeps Tripping

If your AC keeps tripping the breaker, the compressor is probably drawing too much power. Could be a bad capacitor, could be a dying compressor motor, could be electrical shorts. Either way, it needs a tech—don’t just keep resetting the breaker.

Energy Bills Suddenly Spike

A failing compressor works way harder to achieve the same cooling, which cranks up your electric bill. If nothing else has changed but your bill jumped 30-40 percent, check your compressor.

Warm Air Blowing Inside

If you’re getting only warm air and you’ve already checked filters and thermostats, the compressor probably can’t compress refrigerant effectively anymore. At that point you’re just running an expensive fan.

Notice one or more of these? Act fast. Delaying can lead to total system failure and way more expensive repairs.

Step-by-Step Troubleshooting (What You Can Safely Check)

Before calling a tech, there are a few things you can check yourself. But remember—compressors involve high voltage and refrigerant. If these steps don’t work, stop and call a pro.

Step 1: Turn Off Power at the Breaker

Always start here. Electrical safety first. Disconnect power completely before touching anything.

Step 2: Check Your Thermostat Settings

Make sure it’s set to Cool and the target temperature is actually below current room temperature. Yeah, we’ve driven out for service calls where this was the only problem.

Step 3: Inspect Breakers and Fuses

A blown fuse or tripped breaker is common. Replace fuses, reset breakers once. If it trips again immediately, stop—you’ve got a bigger electrical issue.

Step 4: Test the Capacitor (If You Know How)

A bad capacitor can prevent the compressor from starting. They’re cheap to replace. But if you’re not comfortable working with capacitors (they hold a charge even when power’s off), skip this and call a tech.

Step 5: Listen Carefully When You Restore Power

Turn power back on and listen. If you hear clicking but no humming, or grinding noises, that’s internal mechanical failure. That needs a pro.

Safety reminder: Do not attempt to replace the compressor yourself. This requires EPA certification, specialized tools, and refrigerant handling knowledge. DIY compressor work will damage your system and could hurt you.

Repair vs Replacement: Making the Right Call

When Repair Makes Sense

If the issue is a blown fuse, bad capacitor, faulty contactor, or wiring problem, repair is quick and affordable. These fixes cost 150-500 dollars and get you back up and running fast.

When Replacement Makes More Sense

If the compressor itself is mechanically damaged, leaking refrigerant, or your unit is over 10-12 years old, replacement is usually smarter. Here’s why:

- New compressor costs 1,200-3,500 dollars

- Old systems have other worn components ready to fail next

- New systems are way more efficient—lower bills every month

- Full system replacement often costs only 2,000-3,000 more than compressor alone

In Texas where we stress systems constantly, replacing the whole unit often makes more financial sense than patching an old compressor. Your tech can walk you through the math based on your specific situation.

What Kills AC Compressors in Texas

Age of the system: Compressors over 10-12 years are way more prone to mechanical and electrical failures.

Lack of maintenance: Dirty coils, clogged filters, and low refrigerant strain compressors. Regular tune-ups catch these before they cause failure.

Texas climate stress: Hot, humid summers put extra strain on compressors. Units here work harder and fail sooner than in mild climates.

Electrical problems: Voltage spikes, power outages, bad capacitors—all can damage or kill compressors. Surge protectors help.

Constant use patterns: Running AC nonstop without breaks accelerates wear. Texas homes run AC 6-9 months a year, which is brutal on equipment.

Being aware of these factors helps you take preventive steps like annual maintenance, surge protection, and realistic expectations about system lifespan.

Houston HVAC Trends Worth Knowing

Energy-efficient units are becoming standard. Homeowners across Katy, Sugar Land, and The Woodlands are investing in 16+ SEER systems to save on electricity. The upfront cost is higher but monthly savings are real.

Smart thermostats are everywhere now. They reduce unnecessary compressor use by optimizing run times and temperatures. Less runtime equals longer compressor life.

Annual maintenance is finally being taken seriously. With rising summer temperatures, yearly inspections are now considered essential, not optional. Techs can catch failing capacitors and low refrigerant before they kill compressors.

Proactive replacement is a growing trend. Some homeowners are replacing compressors or full systems before they fail to avoid emergency repairs during heat waves. Smart move if your system’s pushing 12 years.

FAQ

How long can I run my AC if the compressor is failing?

Don’t run it at all if you suspect compressor failure. Running a failing compressor can damage other expensive components like the contactor, capacitor, and even the indoor coil. Turn it off and call a technician immediately to limit damage. The longer you wait, the more expensive the repair gets.

Can I replace an AC compressor myself?

No, absolutely not. Compressor replacement requires EPA certification for refrigerant handling, specialized tools, and electrical expertise. DIY attempts usually damage the system beyond repair and can cause serious injury from high voltage or refrigerant exposure. Only licensed HVAC technicians should do this work.

Why does my AC compressor keep tripping the breaker?

Most common causes are a bad capacitor, shorted wiring, aging compressor motor, or electrical overload. A tripping breaker is a safety mechanism telling you something’s dangerously wrong. Don’t keep resetting it—call a technician to diagnose the electrical issue safely before it causes a fire or total system failure.

How much does compressor replacement cost in Texas?

Costs range from 1,200 to 3,500 dollars depending on unit size, brand, refrigerant type, and labor. Sometimes full system replacement (4,500-7,000 dollars) makes more financial sense than just replacing the compressor, especially if your unit is over 10 years old. Your tech can help you weigh the options.

How often should I service my AC to avoid compressor failure?

At least once a year, ideally in early spring before summer heat arrives. Annual inspections catch dirty coils, low refrigerant, bad capacitors, and electrical problems before they kill your compressor. In Texas where systems run constantly, yearly maintenance is essential, not optional. It’s way cheaper than emergency replacement.

John Moore HVAC Services: Compressor Experts Since 1975

At John Moore HVAC Services, we understand how critical a working compressor is in Texas. Our licensed technicians specialize in diagnosing compressor issues, performing professional repairs, and recommending solutions that fit your home and budget.

We’ve been serving the greater Houston area for over 50 years. We know Texas heat, we know what kills compressors, and we’ll give you honest advice about whether repair or replacement makes more sense. Whether you’re in Memorial, The Heights, Katy, Sugar Land, or Pearland, we’re here to help. Give us a call.